Prototyping has always been a critical step in product development. It’s the bridge between an idea and a tangible solution. But traditional methods were often slow, costly, and inflexible.

Today, 3D design tools have transformed the way teams prototype, making the process faster, more accurate, and more collaborative.

In this article, we’ll explore how 3D design helps in rapid prototyping, the benefits it brings to businesses, and why it’s a game-changer for product development.

What is 3D Design in Prototyping?

3D design uses CAD (computer-aided design) software to create detailed digital models of products before they are manufactured.

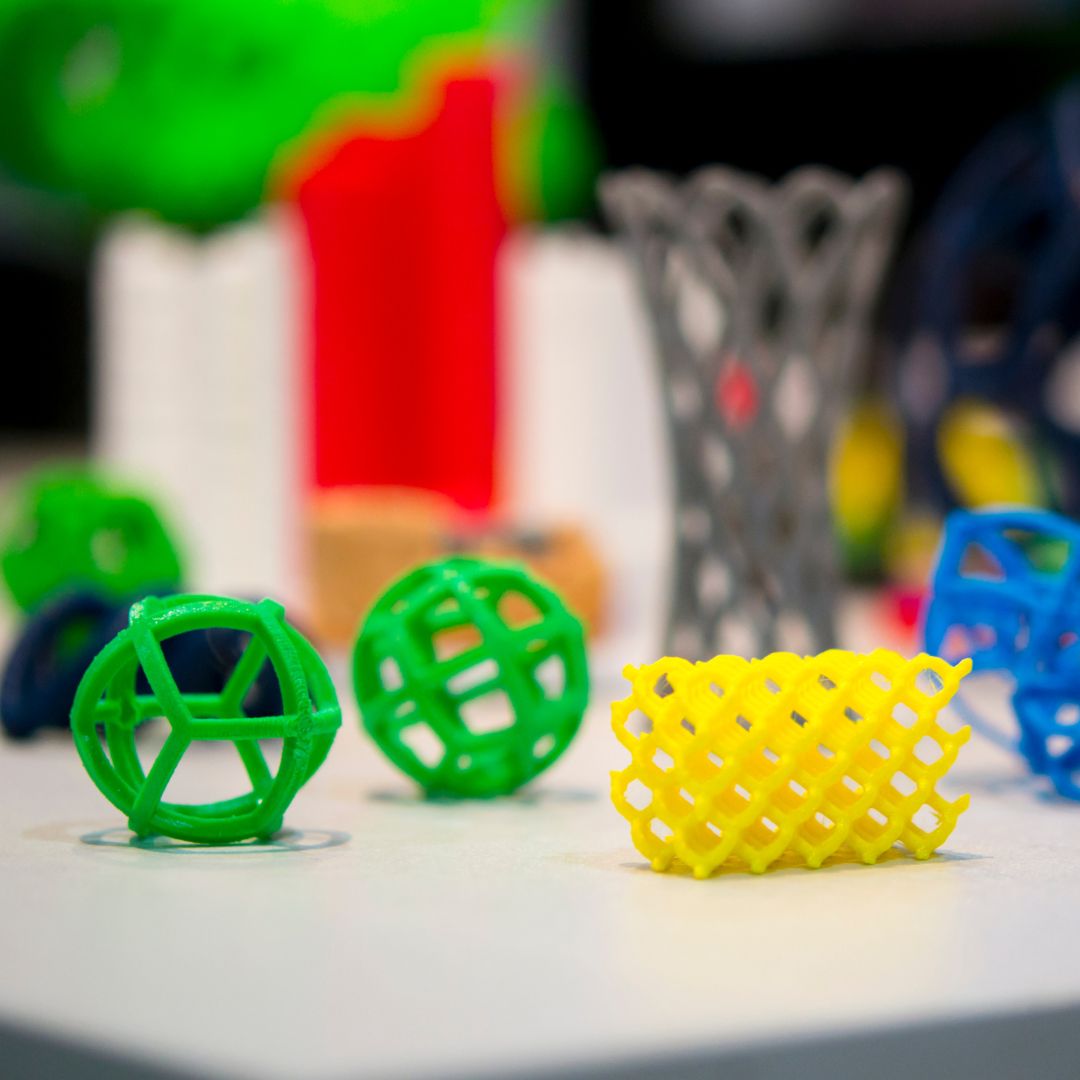

These models can be tested, refined, and even converted directly into physical prototypes using rapid prototyping methods such as 3D printing.

Unlike 2D drawings or sketches, 3D models provide a complete visualisation of a product — allowing designers, engineers, and stakeholders to see exactly how it will function and look in real life.

Benefits of 3D Design in Prototyping

1. Faster Iterations

Traditional prototyping often meant starting from scratch for every adjustment.

With 3D design, modifications can be made directly to the digital model in minutes, accelerating the entire development cycle.

2. Lower Costs

Errors caught in digital prototypes save significant money compared to discovering flaws after physical production.

Businesses can test ideas virtually before committing to expensive materials or tooling.

3. Accurate Testing & Simulation

Modern 3D design software allows engineers to simulate stress tests, material behaviour, and product performance virtually — helping ensure prototypes function as intended before moving into production.

4. Better Collaboration & Communication

3D models are easy to share across teams and stakeholders.

Instead of relying on flat drawings, everyone can see and interact with a realistic 3D representation, improving feedback and reducing miscommunication.

5. Seamless Transition to 3D Printing

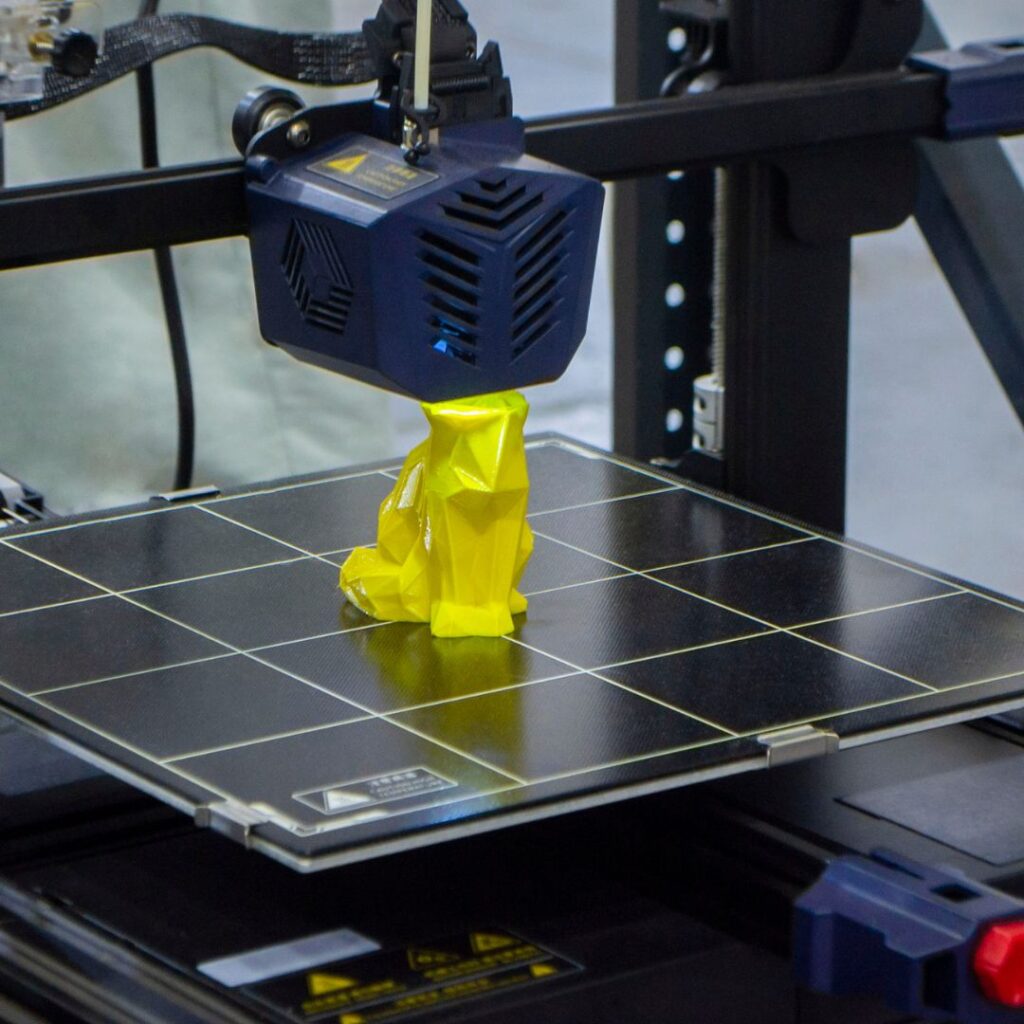

Once the design is finalised, the digital file can be sent directly to a 3D printer to create a rapid prototype.

This reduces lead times from weeks to days — or even hours.

Real-World Example: From Concept to Prototype

Imagine a company designing a new consumer gadget.

In the past, they might have spent weeks hand-crafting early prototypes, only to discover design flaws later. With 3D design:

- Engineers model the product digitally.

- The design is tested and refined through virtual simulations

- Stakeholders review the model in 3D and provide feedback.

- A physical prototype is 3D printed overnight for hands-on testing.

This process allows multiple design iterations in days rather than months — reducing both risk and cost.

Why 3D Design is the Future of Prototyping

The combination of 3D design and rapid prototyping means businesses can innovate faster and more confidently.

From startups building their first product to established manufacturers streamlining development, 3D design helps reduce time to market while improving product quality.

Final Thoughts

3D design isn’t just a tool — it’s the foundation of modern prototyping. By enabling rapid iterations, lowering costs, improving accuracy, and fostering collaboration, it transforms how ideas become real products.

At BDL 3D, we help businesses bring their designs to life through expert 3D prototyping solutions. Whether you’re developing a new product or refining an existing one, our team can support you at every stage of the journey.

Ready to explore the benefits of 3D prototyping? Get in touch with BDL 3D today!