Think 3D printing is just for prototypes or plastic toys? Think again.

From jet engines to dental crowns, entire industries are now relying on additive manufacturing to solve complex problems and streamline production.

Behind the scenes, many modern products – cars, tools, implants, and even buildings — is a quiet revolution in how things are made. With the ability to create parts that are lighter, faster, and often impossible with traditional methods, 3D printing has gone far beyond the lab.

In this article, we’ll explore the industries embracing 3D printing today, the real-world applications driving adoption, and what it means for the future of manufacturing.

Aerospace

If any industry demanded parts that were lighter, stronger, and more complex, it was aerospace. Enter 3D printing.

In aviation and space exploration, weight isn’t just a detail — it’s currency. Every gram saved translates into fuel efficiency, extended range, or room for more payload. That’s why aerospace manufacturers were among the first to embrace additive manufacturing at scale.

Using 3D printing, engineers are now creating components that were once impossible with traditional machining. We’re talking fuel nozzles, turbine blades, heat exchangers, even structural brackets — all produced with internal geometries that optimise strength while cutting unnecessary mass.

For instance, companies like GE Aerospace have utilised 3D printing to develop advanced engine components, enhancing performance and reducing weight. Similarly, Airbus has integrated over 1,000 3D-printed parts into its A350 XWB aircraft, demonstrating the scalability of additive manufacturing in commercial aviation.

In essence, 3D printing is not just enhancing existing manufacturing processes in aerospace; it’s unlocking new design possibilities and operational efficiencies that were previously unattainable.

Automotive

In the automotive sector, 3D printing has evolved from a prototyping tool to a critical part of modern manufacturing. Leading car makers now use additive manufacturing to produce functional parts such as intake manifolds, brackets, and custom fixtures — all with increased speed and reduced waste.

Ford, for example, has embraced 3D printing in automotive production by using it to develop lightweight components and complex geometries for performance vehicles like the Mustang Shelby GT500. This approach has improved turnaround times and cut tooling costs significantly.

BMW has taken things further by using 3D printed car parts in end-use applications and testing aerodynamic prototypes under wind tunnel conditions. This allows for faster design cycles and greater flexibility in developing next-gen vehicle concepts (source).

Beyond vehicle parts, manufacturers are turning to additive manufacturing for custom tooling and jigs that streamline assembly processes. The ability to print on demand — instead of relying on third-party suppliers — helps reduce downtime and accelerates production.

For an industry built on precision, speed, and constant innovation, 3D printing offers a serious performance advantage.

Healthcare

In healthcare, precision isn’t a luxury — it’s a necessity. 3D printing has emerged as a transformative force, enabling the creation of patient-specific solutions that enhance outcomes and streamline treatments.

Customised Implants and Prosthetics

Traditional implants often require adaptation to fit a patient’s unique anatomy. 3D printing flips this paradigm by allowing for the design of implants tailored to individual patients. For instance, the FDA-approved Patient-Specific Talus Spacer offers a custom-fit solution for ankle joint replacement, improving mobility and reducing pain for patients with avascular necrosis.

Similarly, companies like Open Bionics are leveraging 3D printing to produce affordable, customised prosthetic limbs, such as the Hero Arm, which combines functionality with personalisation, catering to both adults and children.

Surgical Planning and Medical Models

Surgeons are increasingly using 3D-printed anatomical models to prepare for complex procedures. These models — often based on CT or MRI scans — give medical teams a tangible, accurate reference to improve surgical precision and outcomes.

Bioprinting and Regenerative Possibilities

While still early-stage, 3D bioprinting is pushing the boundaries of regenerative medicine. Researchers are developing techniques to print soft tissue, bone scaffolds, and even organ structures — offering hope for a future where donor shortages could become a thing of the past.

From hospital rooms to research labs, 3D printing is making healthcare more personal, more efficient, and more advanced than ever before.

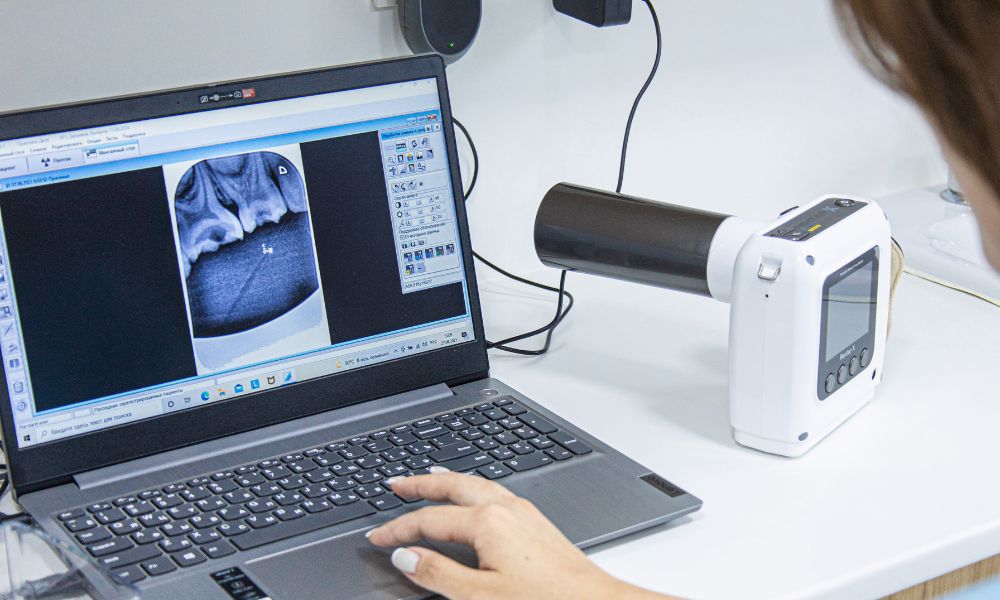

Dental & Orthodontics

Dentistry has been one of the fastest adopters of 3D printing technology, and for good reason. The need for precision, personalisation, and speed makes additive manufacturing a natural fit in everything from orthodontics to restorative care.

- Clear aligners produced at scale – Brands like Invisalign (Align Technology) print over 700,000 custom dental moulds per day to create patient-specific treatment plans

- Same-day crowns and bridges – Dentists can now scan, design, and print permanent restorations chairside, eliminating lab wait times.

- Surgical guides for implant precision – 3D-printed guides help clinicians place implants accurately, improving outcomes and reducing surgery time.

- Digital models replace physical impressions – Scanned files are printed for planning, retainers, or diagnosis — no more uncomfortable moulds.

- Lower cost, faster turnaround – Labs and clinics benefit from leaner workflows, better margins, and happier patients.

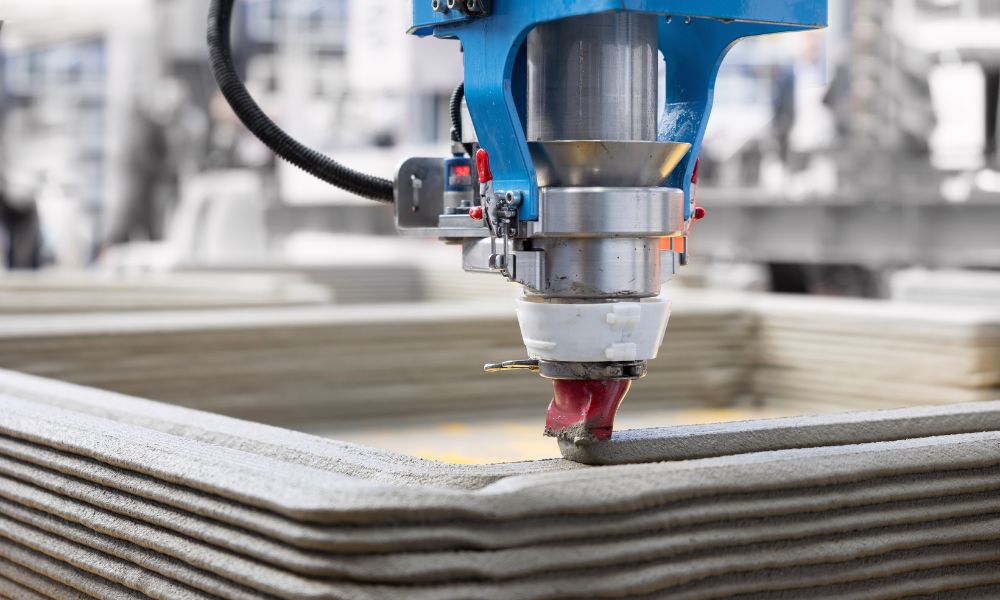

Architecture & Construction

3D printing is reshaping how we design, plan, and even build the spaces we live and work in. It brings speed, flexibility, and creative freedom to an industry often slowed by cost and complexity.

- Architectural models made in hours, not days – Firms use 3D printers to produce intricate scale models quickly, helping clients visualise designs more effectively.

- Concrete 3D printing for housing and infrastructure – Startups and developers are experimenting with large-scale printers to build walls, facades, and entire homes layer by layer.

- Reduced waste, faster build times – Additive construction minimises material overuse and streamlines labour-intensive processes.

- Custom formwork and design elements – Complex curves, textures, or organic forms that would be costly or impossible with traditional methods are now feasible.

- Disaster relief and low-cost housing – 3D printing is being tested to provide rapid, affordable shelter in response to humanitarian needs or housing shortages.

In New Zealand, companies like QOROX have pioneered the use of 3D concrete printing, completing the country’s first fully 3D-printed residential home in Paremoremo and the first commercial building with 3D-printed walls in Hamilton . These projects showcase the technology’s potential to revolutionise construction practices locally.

Conclusion

3D printing has quietly evolved from a niche prototyping tool into a core driver of innovation across industries. Whether it’s enabling lighter aircraft components, streamlining dental workflows, or accelerating architectural design, the technology is solving real-world problems at scale.

From aerospace to healthcare, construction to consumer goods, additive manufacturing is no longer an emerging trend — it’s a competitive advantage. And as materials improve and printers become faster and more accessible, the list of industries embracing 3D printing will only continue to grow.

If you’re ready to explore how 3D printing could apply to your business or project, we offer a full range of services including end-to-end 3D printing, commercial-grade production, rapid prototyping, scanning, and design support. Whether you’re validating a concept or scaling up, our team can help you take the next step with confidence.

FAQ

Which industry uses 3D printing the most?

The aerospace industry is widely considered the leading adopter of 3D printing. It relies on the technology to produce lightweight, complex parts like turbine blades and fuel nozzles that reduce weight and improve performance.

How many industries use 3D printing?

Dozens of industries now use 3D printing in some form, but major adopters include aerospace, automotive, healthcare, dental, construction, fashion, consumer goods, and education. As technology matures, its applications continue to expand.