PA12 (Polyamide 12) is a high-performance nylon widely used in 3D printing and industrial applications.

Whether you’re an engineer, designer, or project manager, understanding how PA12 performs can help you decide if it’s the right fit for your next product or prototype.

In this article, we’ll break down what PA12 is, its properties, advantages, limitations, and where it’s most commonly applied.

What is PA12?

What does PA12 stand for?

PA12 stands for Polyamide 12, also known as Nylon 12. The number “12” refers to the carbon atoms in its monomer building block.

This structure gives PA12 its unique characteristics compared to shorter-chain nylons like PA6 or PA66.

In short: PA12 is a versatile thermoplastic polymer that combines toughness with excellent stability, making it a reliable choice for industries ranging from automotive to consumer goods to 3D printing.

What is PA12 material?

PA12 is part of the nylon family of engineering plastics, but it stands out because of its low moisture absorption, strong mechanical properties, and chemical resistance.

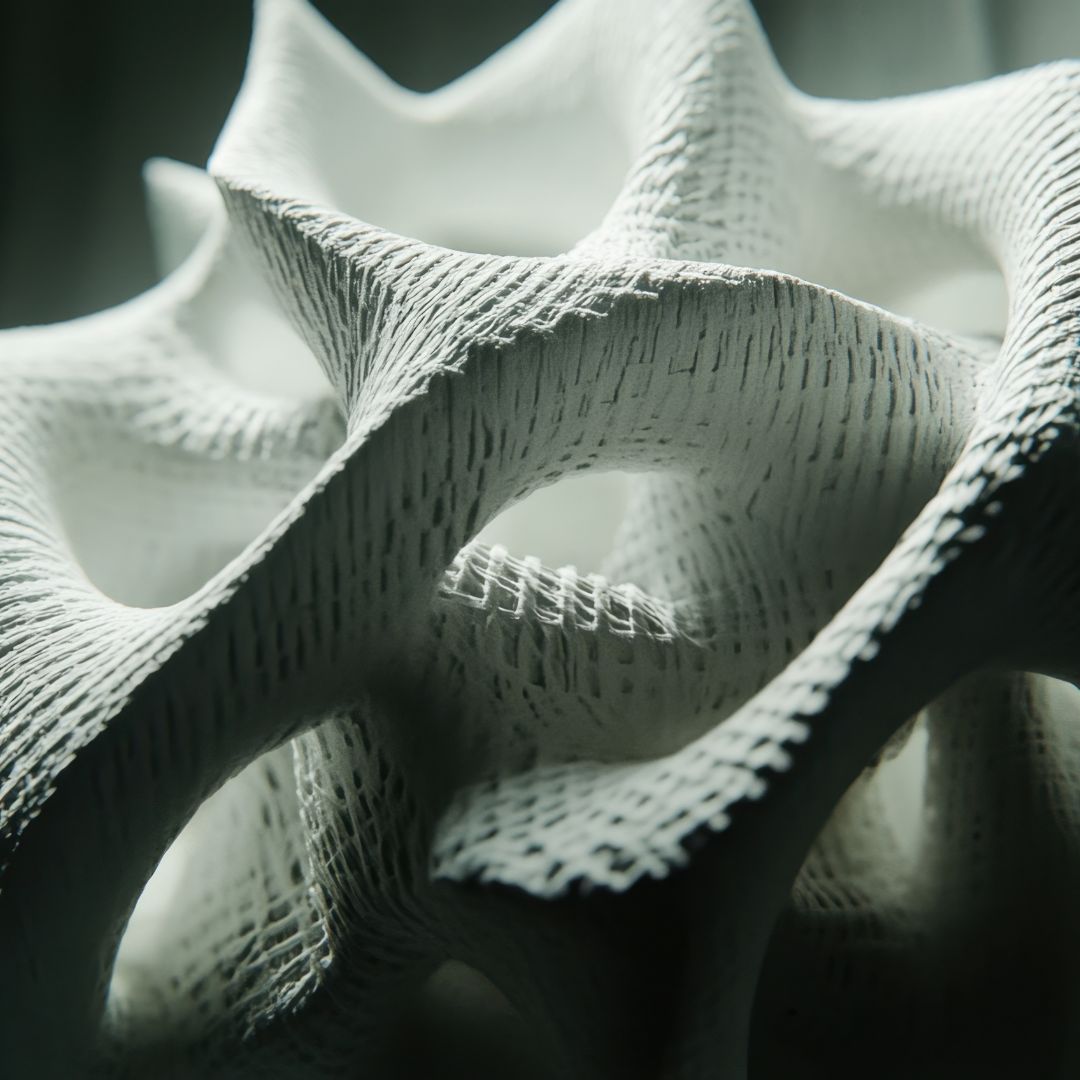

When used in 3D printing, PA12 nylon delivers a strong yet flexible material, capable of producing lightweight parts that maintain dimensional accuracy even in demanding environments.

This makes it ideal for functional prototypes and end-use production parts.

At BDL 3D, we utilise PA12 in many of our additive manufacturing projects due to its balance of durability, flexibility, and chemical resistance.

What are the Advantages of PA12?

Benefits of using Nylon 12

Nylon 12, or PA12, offers a combination of qualities that make it a trusted choice across industries. One of its biggest strengths is low moisture absorption, which means parts keep their shape and size even in humid environments. A critical factor when tight tolerances matter.

Its outstanding chemical resistance allows it to perform reliably in contact with fuels, oils, and solvents where other plastics might degrade.

On top of this, PA12’s toughness and impact resistance means that it can take knocks and stress without cracking, making it a dependable material for both 3D printed prototypes and end-use parts.

Why choose PA12 for industrial applications?

For industrial use, PA12 shines where reliability is non-negotiable.

Its high tensile strength and flexibility let components endure stress without failing, which is particularly valuable for load-bearing or safety-critical parts.

Its thermal stability ensures performance across a wide temperature range, which is one of the reasons why PA12 is so widely adopted in automotive and aerospace applications.

Add to this its abrasion resistance and ability to withstand harsh chemicals, and you get parts that last longer, even in punishing conditions.

While PA12 can be more costly than some alternatives, the longevity and reduced failure rate often make it a cost-effective choice in the long run, especially for additive manufacturing projects.

Comparison with other materials

When compared with other nylons, PA12’s advantages become clearer.

Against PA6, it shows much lower moisture uptake, which translates into superior dimensional stability, critical when consistency across builds is essential.

Compared with PA11, PA12 usually offers better chemical resistance, giving it an edge in harsher environments.

And while it may not be as stiff as some shorter-chain nylons, PA12 strikes a practical balance between strength, toughness, and flexibility, making it especially versatile in 3D printing applications where complex geometries and durability need to go hand in hand.

Limitations of PA12

Common challenges with PA12

Despite its many advantages, PA12 material presents certain limitations. In 3D printing, it requires precise temperature control. Without it, parts can warp or lose dimensional accuracy.

Compared with more common thermoplastics, PA12 is also more expensive, which can be a factor for projects where cost is the main driver.

Another consideration is support removal: depending on the geometry and printing method, cleaning up parts can be trickier than with other materials. These issues are all manageable with the right processes and expertise, but they are worth factoring in when selecting PA12 for your project.

Performance limitations in specific applications

Although PA12 performs well across many conditions, it does have upper limits. Its heat resistance, while strong compared to some plastics, won’t match ultra-high-temperature polymers used in aerospace or electronics.

Similarly, PA12 has limited UV stability. Without additional stabilisers, long-term outdoor exposure can cause degradation.

In terms of strength, its tensile performance is solid but may fall short for applications demanding maximum load-bearing capacity. These factors don’t diminish its value, but they do mean PA12 isn’t the right choice for every environment.

Applications of PA12

Common applications for PA12 in 3D printing

PA12 nylon is one of the most widely used materials in additive manufacturing thanks to its balance of toughness, flexibility, and stability. It’s especially valued for:

- Durable prototypes such as housings, jigs, and fixtures.

- Connectors and tooling that need to withstand mechanical stress.

- Functional prototypes where impact resistance and dimensional accuracy are critical.

Another advantage is its strong layer adhesion, which makes PA12 particularly suitable for producing complex geometries in SLS and MJF processes.

Its chemical resistance also means PA12 parts can be used in environments where contact with oils, fuels, or cleaning agents is unavoidable.

Industrial applications of Polyamide 12

Outside of additive manufacturing, PA12 is a proven material across multiple industries:

- Automotive & Transport: fuel lines, brake system components, and pneumatic hoses where resistance to fuels and oils is essential.

- Aerospace: lightweight components that balance strength with reduced mass, contributing to efficiency and performance.

- Medical: biocompatible parts such as surgical tools, device housings, and other precision components.

- Agriculture & Horticulture: machinery parts and connectors that withstand exposure to chemicals, moisture, and mechanical wear.

- Architecture & Construction: durable fixtures and fittings where dimensional stability is critical under changing conditions.

- Manufacturing & Mechanical Engineering: precision gears, housings, and tooling that rely on PA12’s balance of toughness and accuracy.

- Product Design & Consumer Goods: from footwear and sporting equipment to functional prototypes that demand impact resistance.

- Education & Research: widely used in prototyping and material testing, allowing researchers and students to validate concepts before scaling.

Its high tensile strength ensures parts maintain performance in demanding environments, making it a popular choice for both mass production and customised parts.

Case studies: Successful uses of Nylon PA12

There are countless examples that show how versatile PA12 can be in practice. In the automotive sector, it’s been used in 3D printed components that demand both dimensional stability and resistance to fuels and oils, proving its reliability in harsh operating conditions.

In the consumer goods space, companies turn to PA12 when they need durable prototypes or strong, long-lasting end-use parts.

Its biocompatibility also makes it a valuable choice in the medical field, where safety and performance go hand in hand.

Taken together, these examples underline PA12’s adaptability and its ability to meet demanding requirements across different applications.

With its excellent thermal and mechanical properties, it’s no surprise that PA12 continues to be one of the most widely adopted materials in both prototyping and production.

Using PA12 in 3D Printing

Can PA12 be used in 3D printing?

Yes, PA12 can be used in 3D printing, and it’s actually a popular choice for several reasons. It works well with technologies such as Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF), and is also available as a filament for Fused Deposition Modelling (FDM).

These processes allow engineers and designers to produce complex geometries with excellent accuracy and strong mechanical properties.

Thanks to its toughness and reliability, PA12 is well-suited for both functional prototypes and end-use production parts.

Is PA12 the Right Choice for Your Project?

PA12 (Polyamide 12) has earned its reputation as one of the most versatile engineering plastics in both traditional manufacturing and 3D printing.

With its low moisture absorption, chemical resistance, and toughness, it performs well in demanding environments where reliability matters.

At the same time, it does have its limitations — particularly around high heat, UV exposure, and cost, which means it isn’t always the perfect fit for every application.

For many industries, from automotive and aerospace to consumer goods and medical devices, PA12 strikes the right balance between strength, flexibility, and dimensional stability.

It’s this balance that makes it a go-to material for functional prototypes and end-use production parts in additive manufacturing.

Choosing the right material ultimately depends on the requirements of your project.

If you’re weighing up PA12 against other options, the team at BDL 3D can help you assess its suitability and guide you towards the best solution. Whether that’s PA12 or another advanced material.